WHO WE ARE

The company with innovative solutions

Welcome to BMW Steels Ltd.

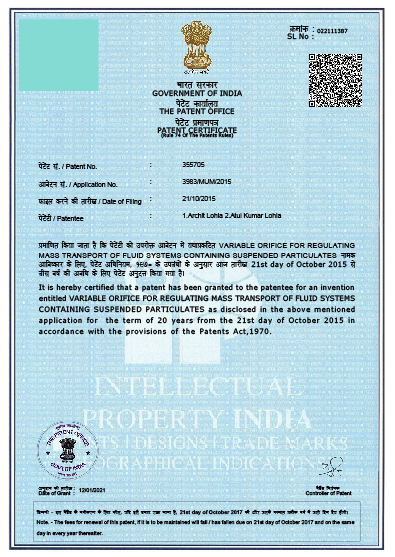

BMW Steels Ltd. was founded in 1990. Our head Office is in Dehradun, Uttarakhand, India. We offer state-of-the-art Engineering solutions for Coal Power Plants, Steel Plants, and Cement Plants. We always visualize the special needs of our customers. Our Engineering Solutions are aided by AI solutions to achieve modal-based designs & simulation. We always believe in quality & efficiency in our products. Our company has an experience of 35+ years in the field of Coal Conveying & Ash Conveying pipeline systems along with advanced engineering tools to collect accurate data for Coal flow.

.png)

.png)

.png)