Our Alumina Ceramic Manufacturing Plant

BMW has state of the art manufacturing facility of Ceramic liners situated at Khurja in Uttar Pradesh.

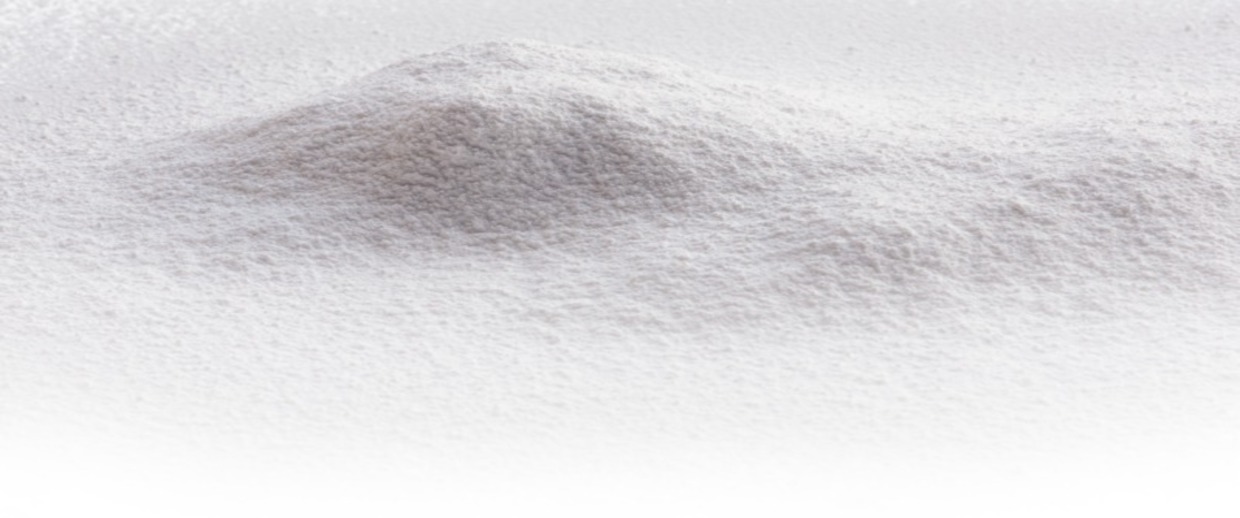

Sintered Alumina Powder Manufacturing

Sintering is the process of forming a densified solid mass of alumina with heat and oxidising atmosphere without melting. The multistep process requires that the powder be mixed with organic binders and lubricants then pressed into shapes.

Post pressing firing process is undertaken so that the binder and lubricants be removed to achieve required density and strength. After the binder has been removed the alumina particles begin to attach to each other through surface diffusion. Finally the pressed part shrinks as the porosity is removed increasing the densification.

Alumina Ceramic (ALUMINA92®)

BMW registered brand for Alumina ceramic is ALUMINA92®. It is sintered and fused Alumina Powder. It is very hard, wear-resistant, and corrosion-resistant ceramic material. It is valued for its outstanding strength against impact, resistance to acid and alkali and wear properties.

It can be shaped through various methods including die pressing, isostatic pressing, slip casting and extrusion. It’s sintered crystalline structure is similar to that of sapphire and ruby. Alumina ceramic is primarily used as an abrasion resistant material for Coal and mineral conveying line and components

Alumina Ceramic

Download Now.png)

92%Fused Alumina Powder with additives after spray drying ready for pressing

.png)

Alumina Ceramic Tiles after hydraulic pressing ready for sintering at 1550°C

.png)

Tunnle Furnace for Alumina Sintering

.png)

Sintering Process of Alumina Ceramic

Typical Properties of Alumina Ceramic (ALUMINA92®)

| Alumina Content | 90-92% |

| Bulk Density | 3.6 GM/CC Min |

| Hardness | 9 on Moh’s scale |

| Water absorption | 0.1% (NIL) |

| Compressive strength | 7000 Kg/Cm² |

| Flexural Strength | 2200 Kg/Cm² |

| Abrasion by Rubbing | 0.1 gm (max) |

| Coefficient of Thermal Expansion | 7 X 10-4 mm°C (min) |

Our Alumina Ceramic Products

1. Alumina Ceramic Liner

BMW manufactures Alumina Ceramic liner in various sizes as per the varying requirement of different clients. Ceramic liners are produced in the form of Flat & Curved Tiles, Cylindrical Sleeves, L shaped Tiles, Wedge Shape Tiles, Ball mill Tiles etc. Ceramic tiles can be of both wieldable and past able type depending upon the area of their application.

.png)

.png)

.png)

.png)

.png)

.png)

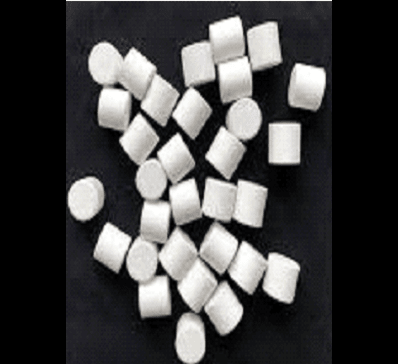

2. Alumina Ceramic Grinding Media Balls & Cylpebs

Grinding media balls & Cylpebs are manufactured for their use in different ball mills for grinding and crushing of various materials to finer particles. These balls and Cylpebs can be of different sizes depending upon the requirement of various clients.

3. Alumina Ceramic Lined Components for Power Plant

Ceramic lined mill spares used in major coal plants including items like Pipes, Bends, Y lateral, MPO, MDV, Innercone, Orifices etc. are ceramic lined in order to reduce their rate of erosion and enhance their overall working life.

.jpeg)

.png)

.jpeg)

.png)

.png)

.png)

.png)

.png)